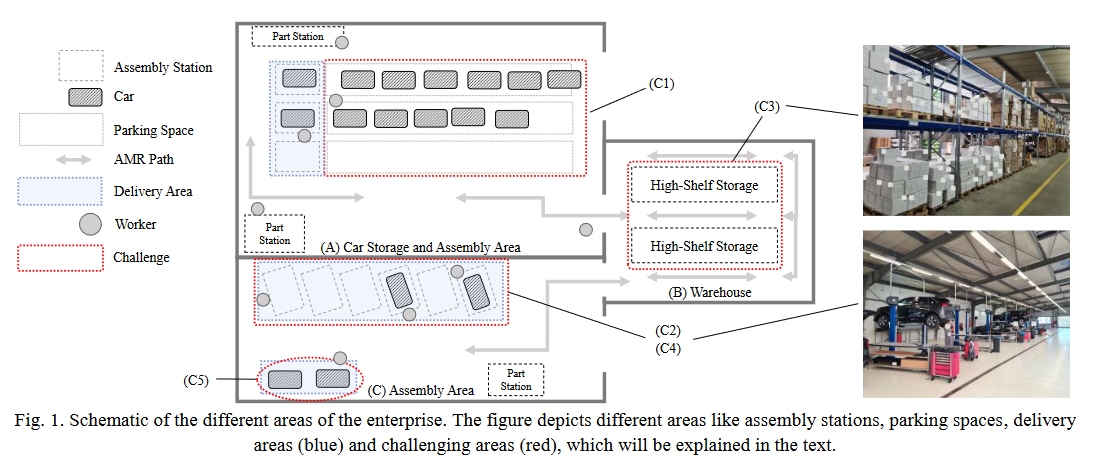

Although the usage of autonomous mobile robots (AMRs) has many advantages, the implementation of AMRs is often hindered through expensive programming, unfavorable process requirements and insufficient operator interaction possibilities. In this paper, we present an analysis of the intralogistic processes in the technical centers of a large automotive logistics enterprise and discuss the challenges of AMR implementation. Based on this analysis and our previous research on an intuitive control software, we present a concept on how to implement flexible and intuitive process control for AMRs. This includes the definition of a visual programming interface, an extended human-machine-interface (HMI) that improves communication between operators and AMRs, and a planning tool that manages multiple AMRs and operators. The results of our process analysis in the selected enterprise show that the design of the shop floor, process flexibility and the task itself, which often requires human interaction with the AMR, are challenges that hinder the implementation of current AMRs. This is mostly attributed to the AMRs requirements of a mostly static environment and process structure. Especially ad hoc changes to the process that needs to be implemented immediately are often required and cannot be realized with usual AMR software. Therefore, our interface concept strongly couples the programmed AMR routines with our HMI on mobile devices that are carried by each operator. This way, we provide flexible interaction between AMR and operators. We further discuss how we plan to implement and evaluate our proposed concepts and tools within the presented enterprise.

The complete article can be accessed here: https://doi.org/10.1016/j.procir.2023.08.028